Become a leader in the IoT community!

Join our community of embedded and IoT practitioners to contribute experience, learn new skills and collaborate with other developers with complementary skillsets.

Join our community of embedded and IoT practitioners to contribute experience, learn new skills and collaborate with other developers with complementary skillsets.

I am thinking of doing a smart watch project this summer (wants to try a big project ) .

and here is the feature which I want to include, apart from which a common Smart watch has!

Is it possible to do?.

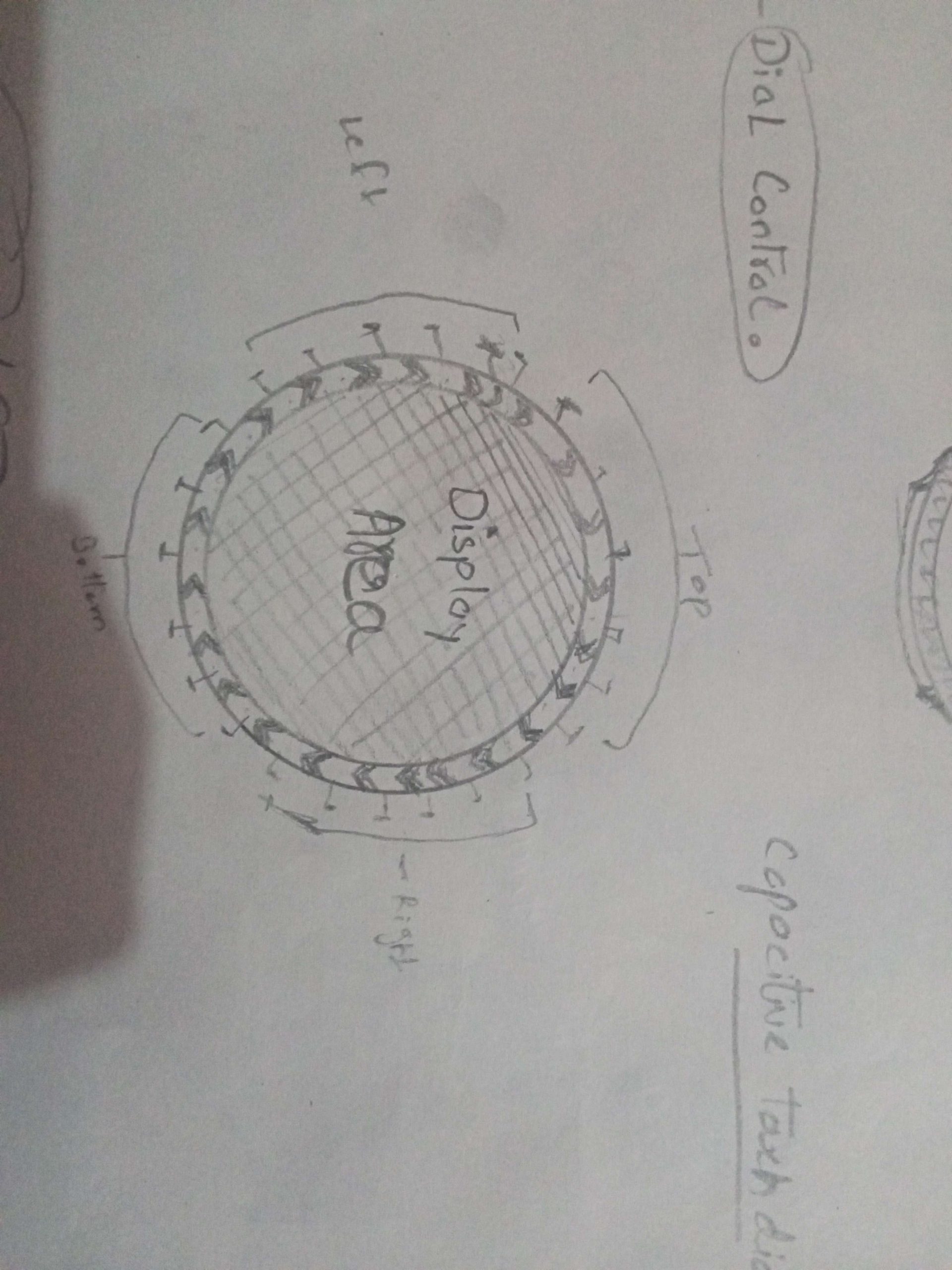

A round capacitive dial with no buttons in the watch!.

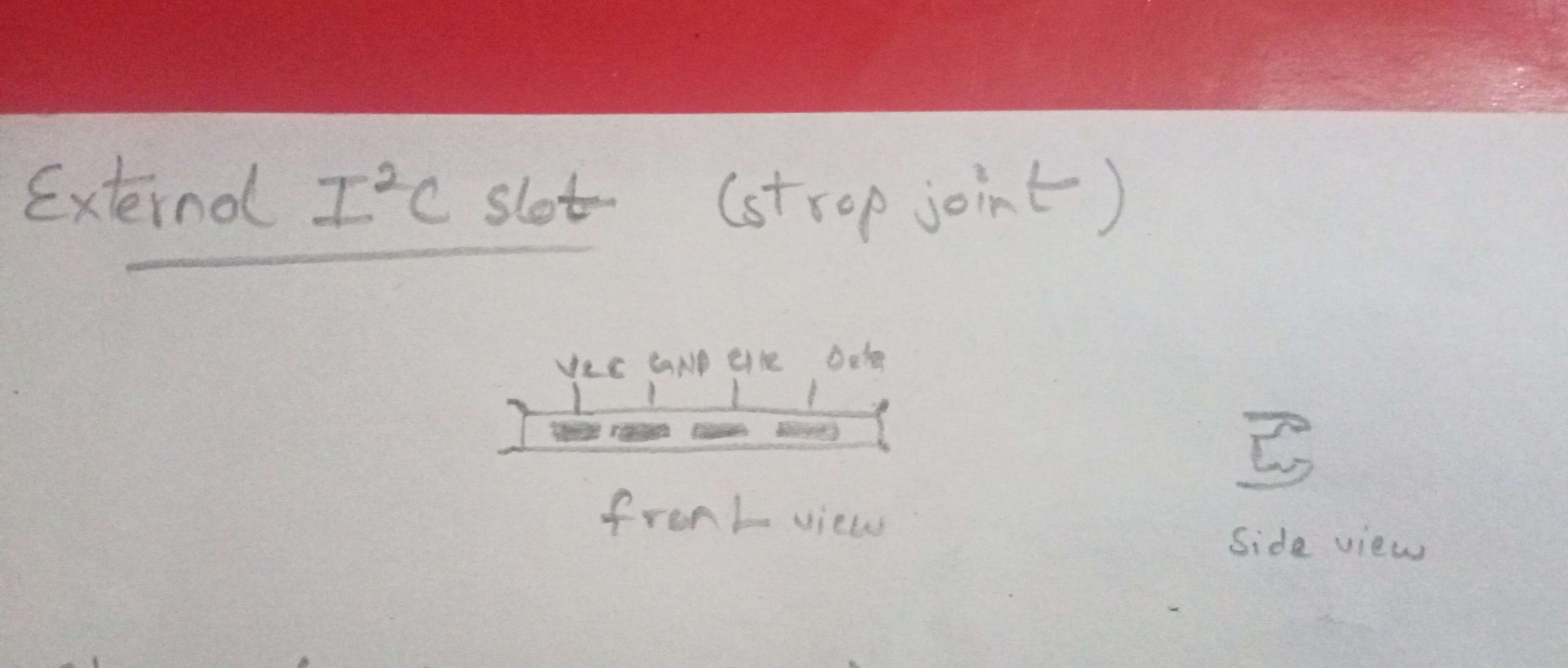

Ab i2c slot embedded in the strap joint so that different sensors can be implemented in the strap instead of the watch!.

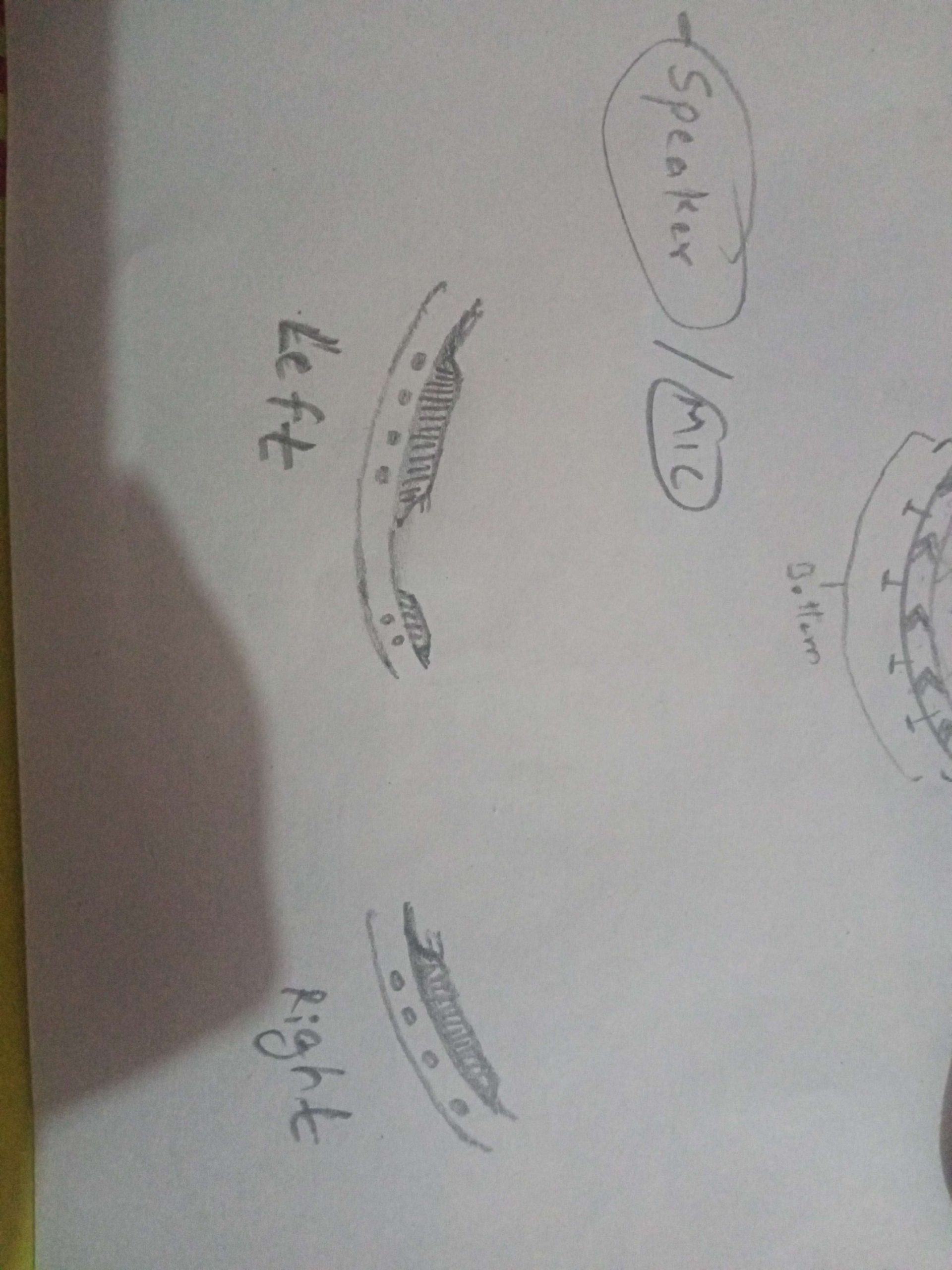

Here is the speaker and mic!

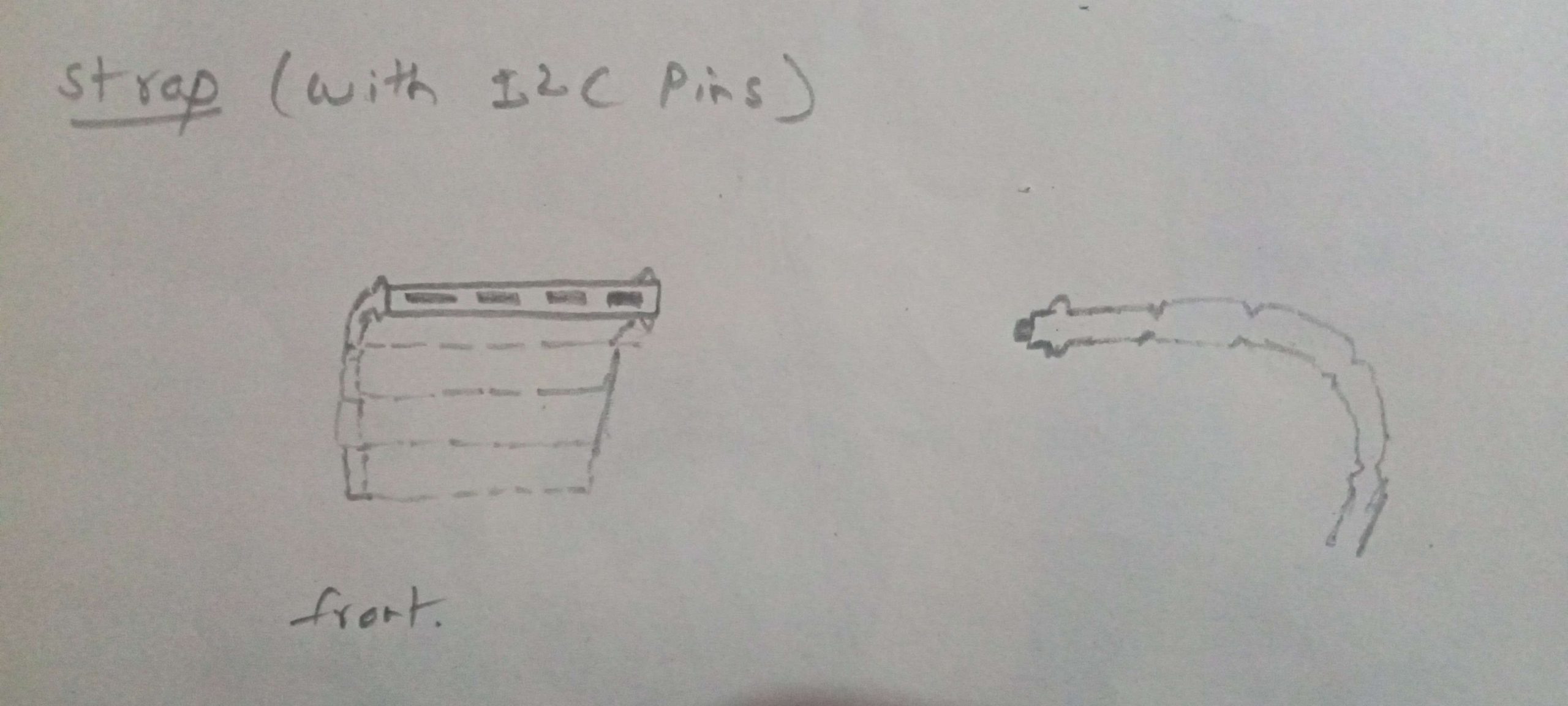

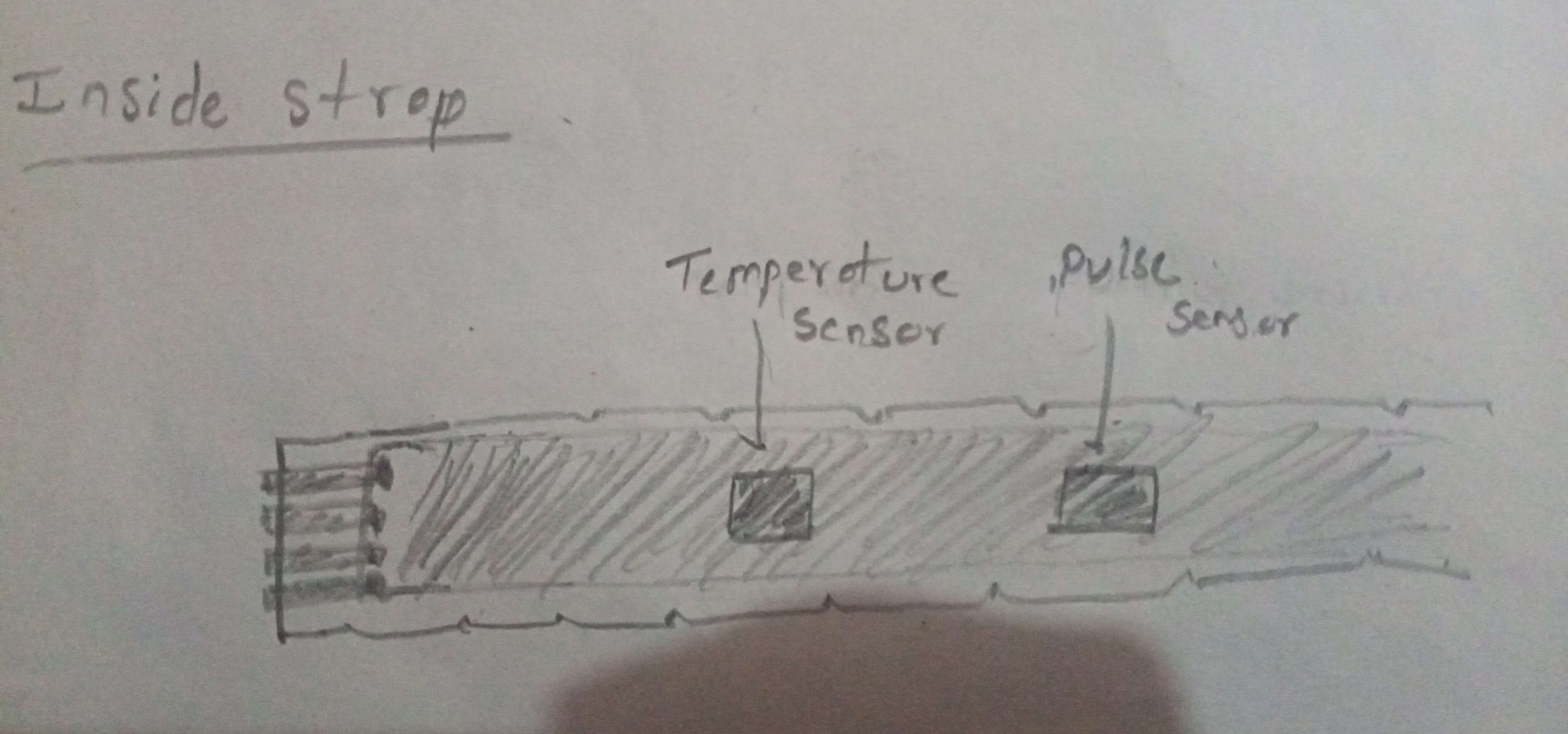

Here strap!.

Sensors can be implemented like this!

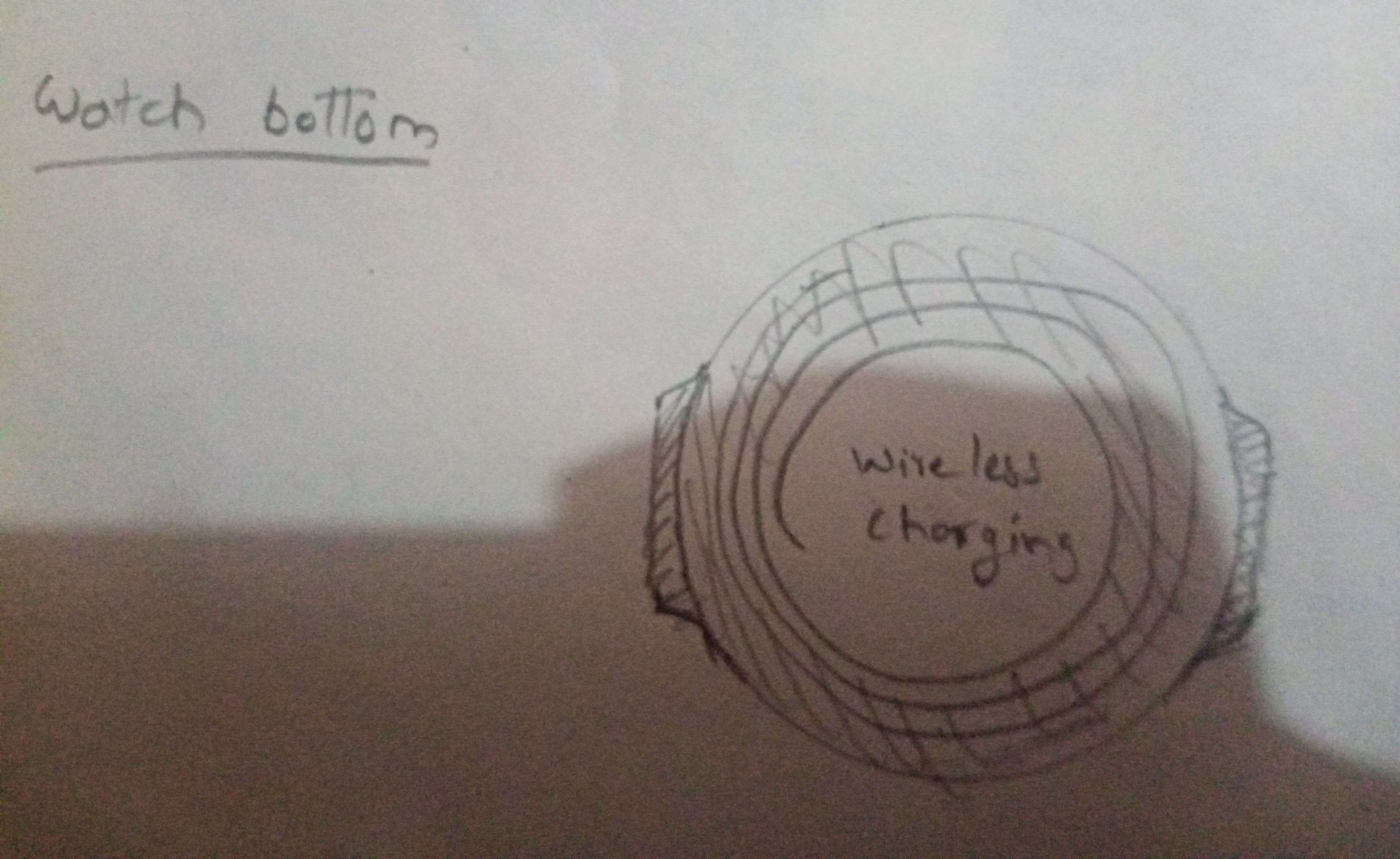

And a wireless charger at the bottom!.

No sensor at the bottom of the watch so that it can be made waterproof!.

The capacitive dial sensor is quite clever, and TBH I’m kind of surprised you don’t see that already. Seems like it would be very doable with a custom PCB. 👍

I think the strap I2C connection is going to be a challenge. It’s a neat idea, but given the potential/repetitive stress on that joint, I think it’s going to cause problems. If you were going to do something with the strap, perhaps with custom pins that electrically conduct on each side. So potentially positive, ground, SCL, SDA. Or you have positive and negative on each side of the strap, lighting them up based on the watch or some other function.

That being said, I myself would stick with the dial for your first try, but if you really want a challenge, then don’t let me disuade you too much!

Well i will try that, can you tell me what I should start with first?

Cad model, pcb design or firmware?

Personally, I would probably start with the PCB design. You could do a functional prototype with the PCB to test out the capacitive dial sensor and use some sort of DIY straps to get it at least sort-of working. That would let you prove things out a bit and tell you how much room you need. You’ll need firmware, of course, but if you look around for other DIY watches, you might be able to find some code that you can modify or at least use as inspiration.

Actually, I would start looking at what others have done first. Here’s one example: https://www.hackster.io/news/mechwatch-pcb-watch-ready-for-everyday-use-140a169aa728 but there are many others.

OTOH, I’m probably a bit biased here, because the capacitve ring part of the design is the most interesting bit IMO, so I’d love to see that proven out! Anyway, all the best with your project!

CONTRIBUTE TO THIS THREAD